BERNOLD SHEET

BERNOLD SHEET

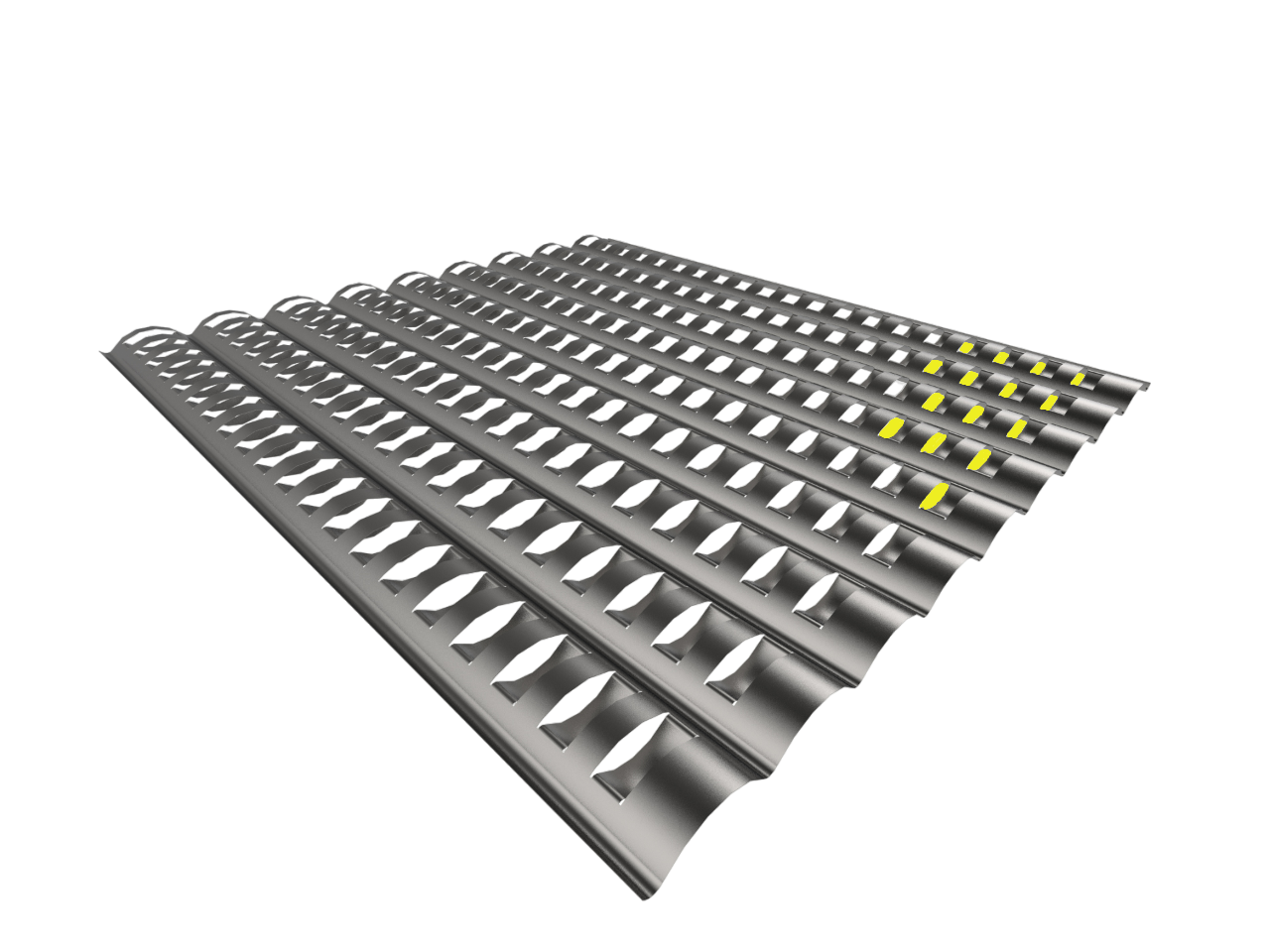

The Bernold Sheets are used as a complement to the use of trusses as primary support. Onix Underground offers Bernold Sheets for use as lost formwork and reinforcement. This type of sheets can also be used to prevent small detachments within the excavated section.

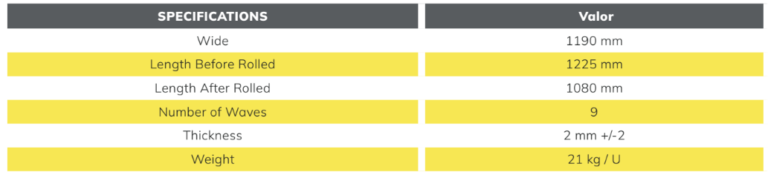

The stamped and corrugated Bernold sheet has a dimension of 1190×1080×2 mm, and its assembly, taking into account the overlaps between each plate, results in a useful coverage of 1 m2.

The presentation of the plates can be straight or curved, depending on the geometry of the truss on which it will be mounted.

ADVANTAJES OF ITS USE

Allows for heavy loads and immediate loading

Resistance to deformation and breakage

Serve as formwork

Creation of false tunnels commonly used in portals

FIELDS OF APPLICATION

Road and railway tunnels

Water and sewer tunnels as it can withstand hydrostatic pressure

Mining tunnels

TECHNICAL PROPERTIES