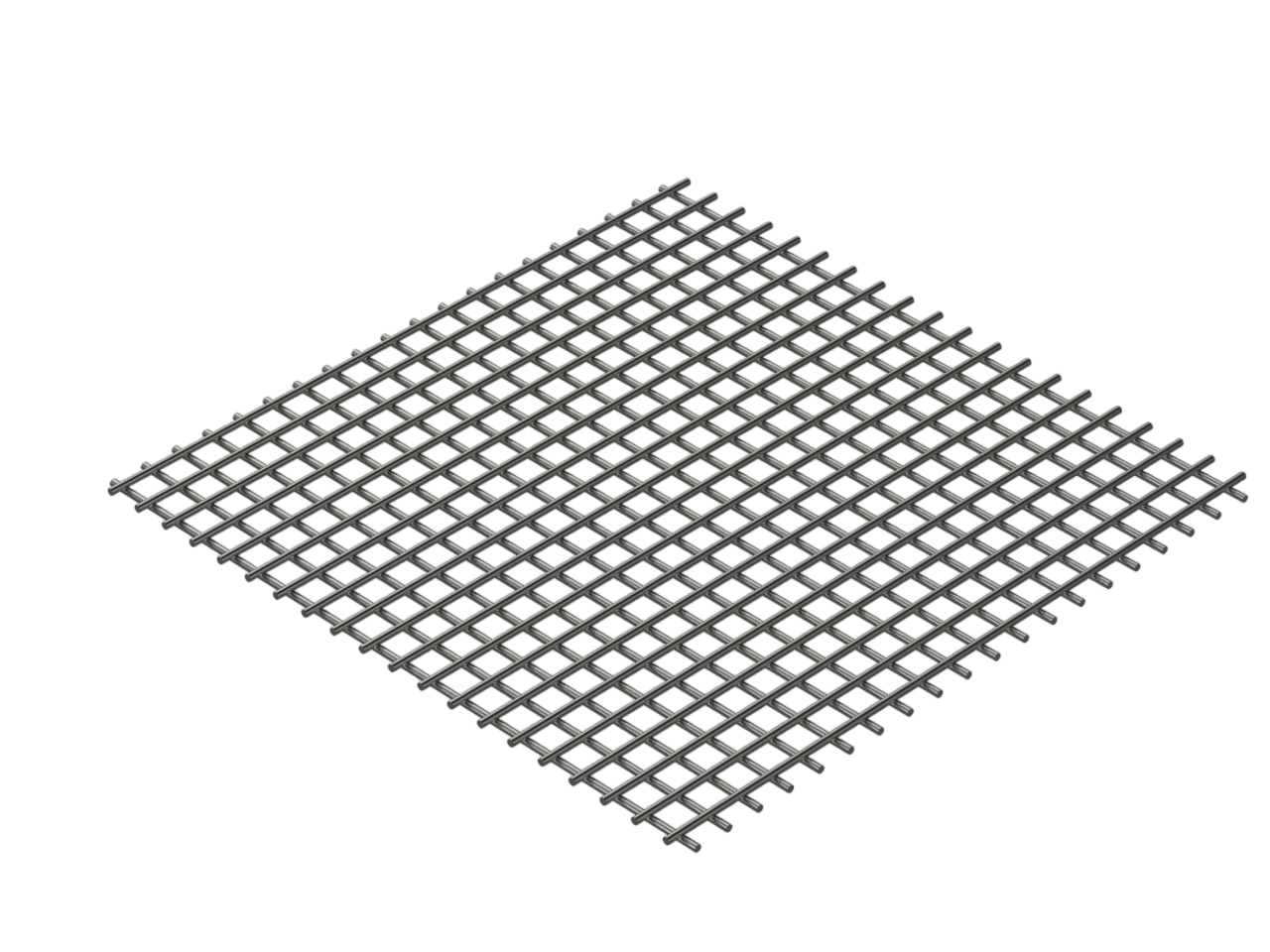

ELECTROWELDED MESH

ELECTROWELDED MESH

The Electro-welded mesh is a type of safety material used in underground mining to protect workers from possible rockfalls or mineral fragments. It is made of high tensile steel wire and is attached to the walls and ceilings of underground excavations to provide a protective barrier that prevents falling rock and ore fragments striking workers.

In addition, the electro-welded mesh also helps to stabilize the excavation area and prevent rock collapse. Welded mesh is installed in sections and attached to the walls and ceilings of the excavation with staples or steel nails.

ADVANTAJES OF ITS USE

High-security support system protecting the entire underground excavation area

It is flexible, adapting to the movements of the terrain

High resistance at its welding point

It can be installed while reinforcing the terrain with bolts, combining both systems

FIELDS OF APPLICATION

Underground mining

Protection and safety in underground projects

Rock stabilization and collapse prevention

Slope stabilization and landslide prevention

Controlling rock fragmentation

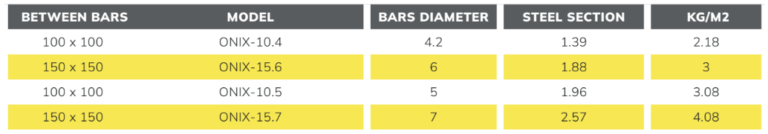

TECHNICAL PROPERTIES