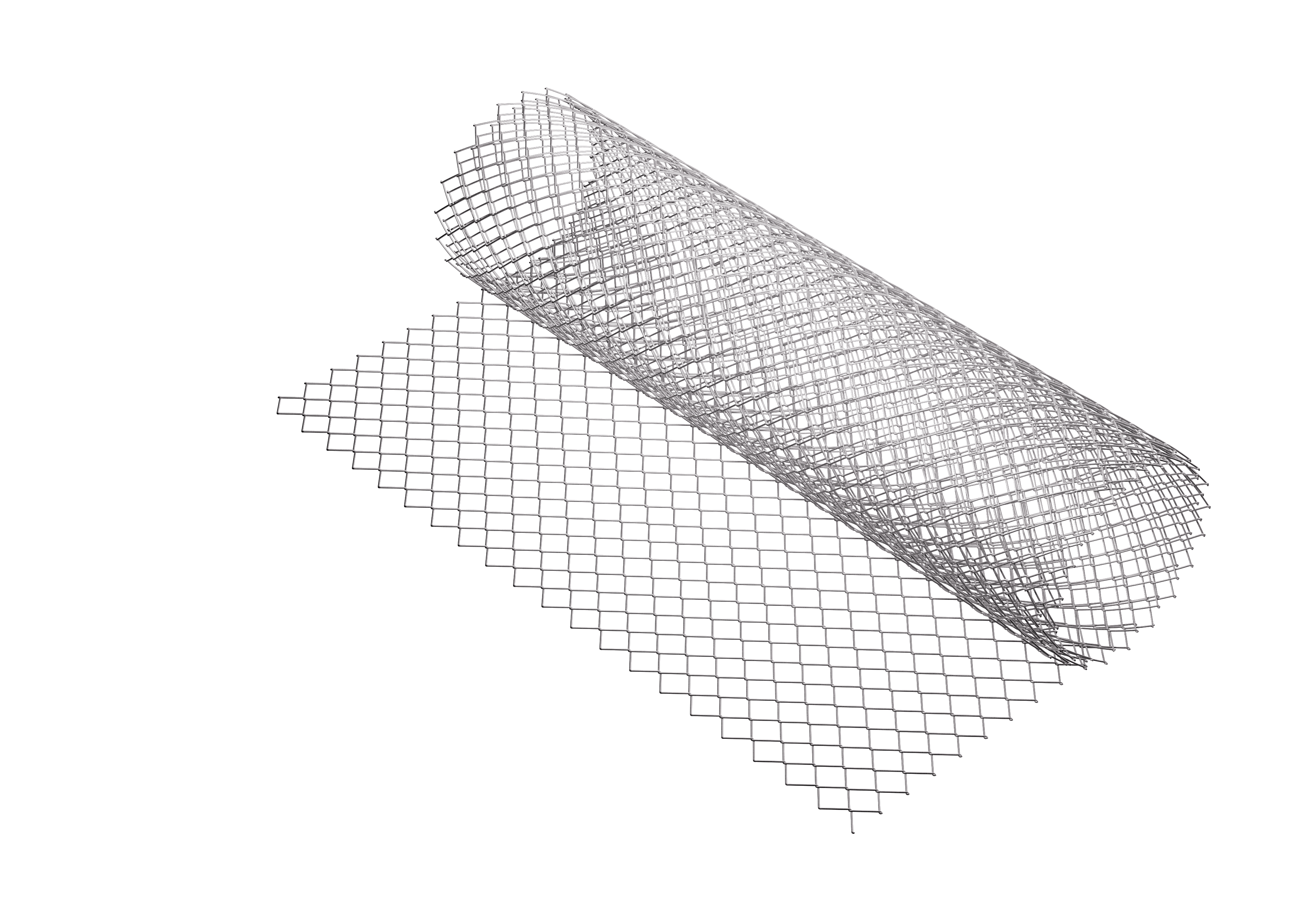

GALVANIZED WOVEN MESH

GALVANIZED WOVEN MESH

Galvanized woven mesh is a type of wire mesh that is produced by weaving galvanized steel wire. The galvanizing process involves coating the steel wire with a layer of zinc to protect it from corrosion and increase its durability.

ADJANTAJES OF ITS USE

Corrosion resistant

Greater adaptability to the rock mass

Easy handling and installation

Higher load resistance than standard woven meshes

FIELDS OF APPLICATIONS

Mining and support projects

Retaining pillars

Slope control

Rock mass retention

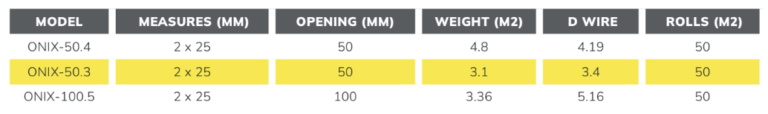

TECHNICAL SPECIFICATIONS