EXPANDABLE ROCK BOLT

EMC EXPANDABLE ROCK BOLTS

The expandable rock bolts are a stabilization device for rock masses in mining and underground works. They are made up of a high elastic limit steel tube, bent into an omega shape, and sealed at the ends with ferrules.

Once inserted into the hole drilled in the rock, which must have a larger diameter than the original diameter of the tube, they expand through the application of water under pressure. This process causes the anchoring bolt to be loaded, and offer immediate support. This is achieved thanks to the action of two types of forces; the first force- a radial pressure perpendicular to its axis along its entire length, and the second force- a frictional force along its entire length.

ADVANTAJES OF ITS USE

Quick installation

Immediate reinforcement of the rock mass

Wide range of applications

Does not require adhesion elements

Excellent performance against vibrations

FIELDS OF APPLICATION

Underground mining

Tunnel construction

Slope stabilization and other geotechnical structures

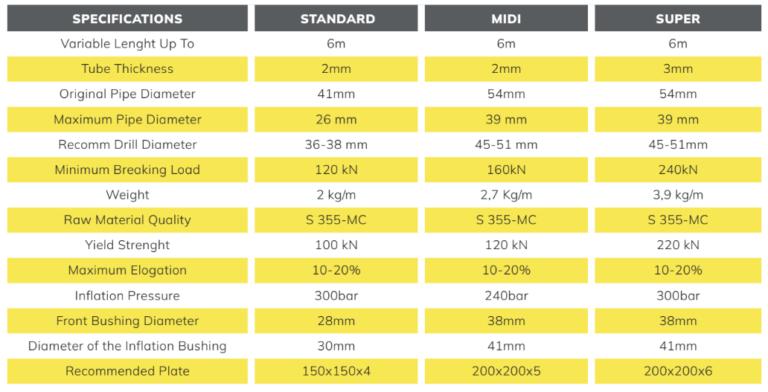

EMC ROCK BOLT TECHNICAL PROPERTIES

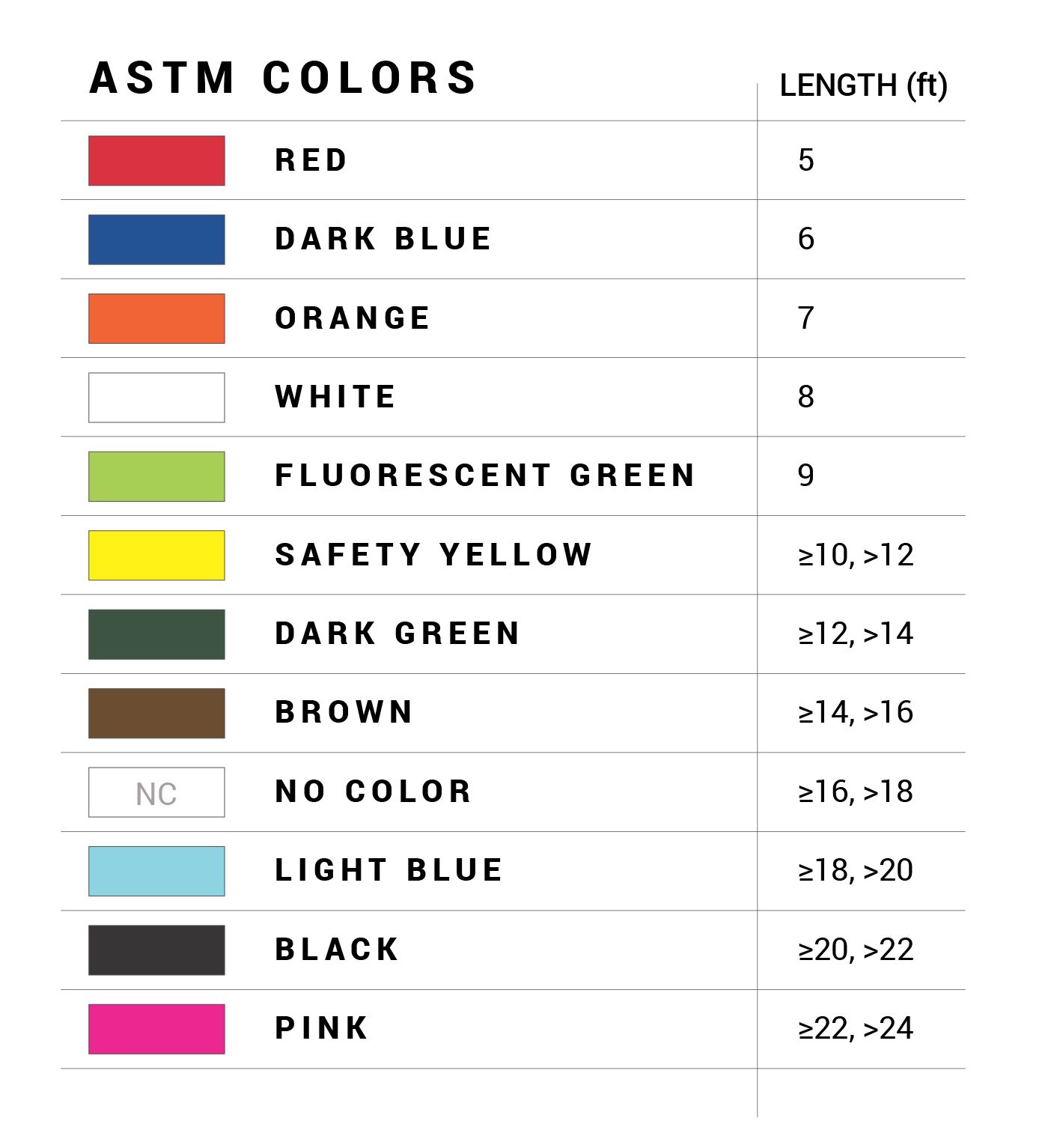

We offer colour taps to protect the rock bolt when it is inserted to the hole and to identify the lenght of the bolts by the ASTM rules. The colour taps can be customizable with the logo of your company.