POLYPROPYLENE FIBER

POLYPROPYLENE FIBER

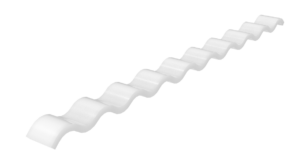

Polypropylene fiber is a type of material used in underground mining and tunnels to reinforce support and improve the stability of excavations. Polypropylene fiber is composed of synthetic polymers, such as polypropylene or polyethylene, and is presented in the form of long, thin fibers.

Polypropylene fiber is used as additional reinforcement in combination with other materials, such as concrete, shotcrete, and anchor bolts, to improve the strength and durability of underground structures and excavations.

ADVANTAJES OF ITS USE

Supports heavy loads, lightweight, and easy to handle

Corrosion resistance. Does not rust

Increased durability. Better fatigue resistance

Flexibility. Adapts better to changes

FIELDS OF APPLICATION

Concrete reinforcement

Ground support

Tunnel linings

Voids filling

TECHNICAL PROPERTIES

Different presentations: 4Kg boxes and Big-Bag.

Minimum recommended dosage: 4-5kg/dm3.

Common shipments in 20′ container: Presentation in 4kg bags of paper;, 4 bags per carton; 36 boxes per pallet. Making 576kg per pallet.

In this 20′ container we load 10 pallets making a total of 5760kg.