STEEL FIBER

STEEL FIBER

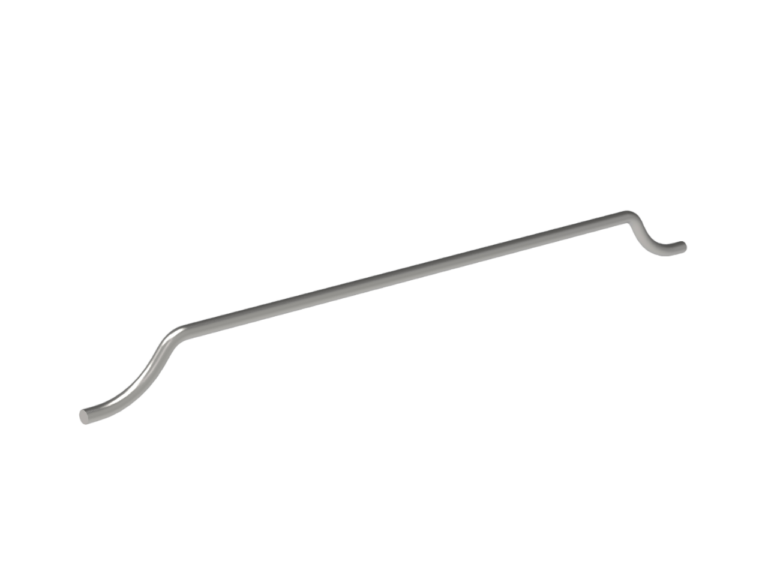

The steel fiber used in underground mining or tunnels is a material composed of high-strength steel filaments that are used to reinforce the support of the ground in underground excavations.

It is manufactured from a cold drawing process, which transforms the steel into filaments of high resistance and durability.

The steel fiber is used as a complement to other ground support systems, such as anchor bolts, wire meshes and support arches. Its main function is to improve the support and resistance capacity of the ground, avoiding the deformation or collapse of the excavation.

ADVANTAJES OF ITS USE

Reinforcement is increased in irregular terrains

Tensile, flexural, and shear properties of shotcrete are enhanced

Quick application

Reinforces the physical cohesion of concrete

FIELDS OF APPLICATION

Construction

Civil engineering projects

Underground mining

Tunnel construction and sanitation

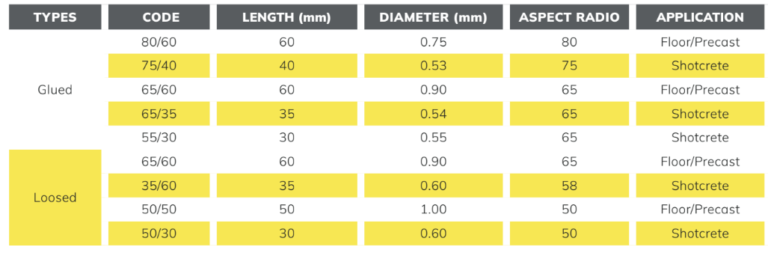

TECHNICAL PROPERTIES OF THE STEEL FIBER